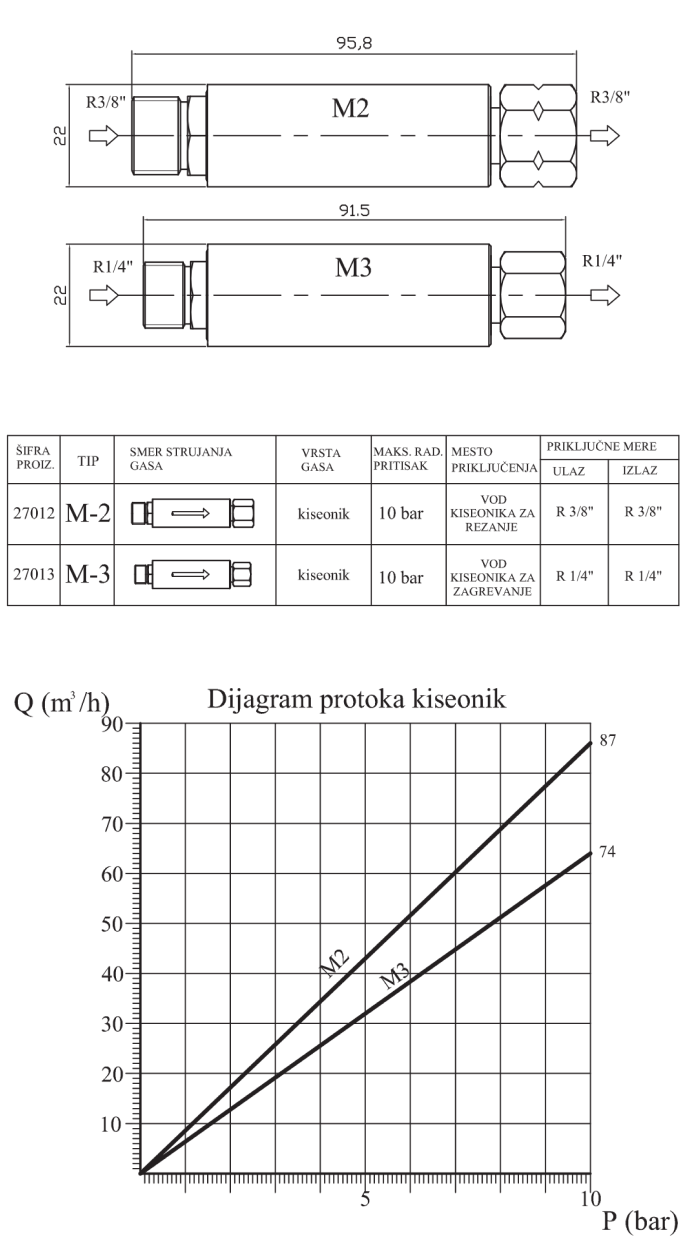

for machine oxygen burners

Dry anti-flame fuses are constructed so that the gas, upon entering the fuse, opens the non-return valve (1) and continues to flow through the sinter insert (2) and the openings in the joint support (3) to the machine burner. The direction of gas flow is indicated by an arrow on the fuse body. When there is a return of the flame due to the explosion, which then occurs, there is an increase in pressure inside the fuse. The pressure acts on the non-return valve, closing it and preventing further gas flow from the installation or cylinder. The return blow of the flame enters the space between the sinter sleeve (2) and the fuse body (4), the gas passes through the sinter cartridge, cools down and since there is no contact with the new gas, it is extinguished and prevents its further spread. This fulfills the basic purpose of fuses M-1, M-2 and M-3.